Q: Can Ga based liquid metals be applied to anodized aluminum heat sinks?Ī: There are published papers that indicate that anodization can prevent the gallium dissolution. As the immersion liquid comes into contact with the liquid metal, I can see the possibility of displacement that potentially pushes some of the liquid metal out from under the interface. Q: Is the liquid metal TIM compatible with immersion cooling technique?Ī: To my knowledge, this has not been studied but it seems like it would be risky. This all depends on the metals being used and the exposure temperature.

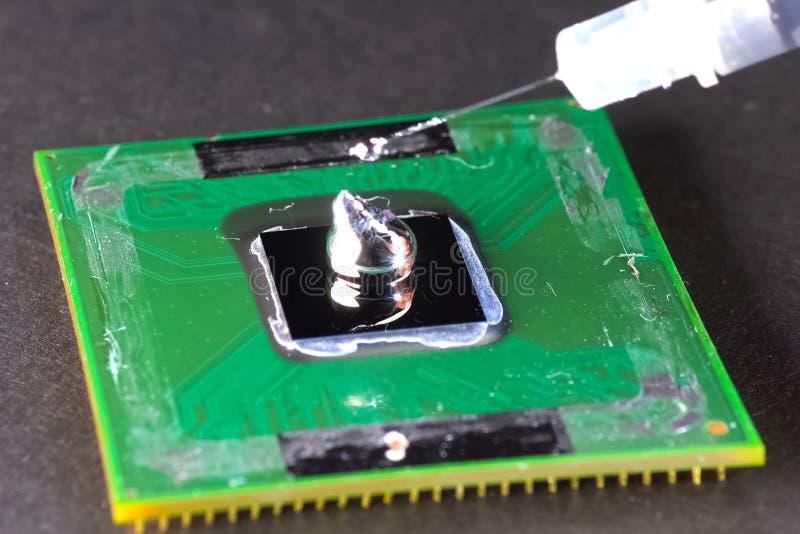

Likewise, it is possible for the liquid metal to dissolve metal from surfaces it is in contact with. For example, if there are solid particles that are soluble in Ga, they will dissolve into the liquid over time. Q: Does the physical structure of these hybrids change over time during thermal cycling or power cycling?Ī: Depending on the composition of these hybrid TIMs, it is possible for their structure to change over time. At some point, if you massively over apply the liquid metal to the interface, it will be possible to have the liquid flow. This is similar to water between glass microscope slides. The adhesive forces of the metals to the other surfaces prevent it from flowing out of the interface. Q: Can these liquids or solid-liquid hybrids be mounted in a vertical position?Ī: As long as you are working with a relatively thin bond line, these materials can be oriented vertically. You may also select materials based on solubility, corrosion resistance, and tendency to oxidize. Ideally, you want something higher in thermal conductivity to improve the overall performance of the system. First is the thermal conductivity of that material. Q: How do you decide which materials to mix with the liquid metals to make a hybrid solution?Ī: There are several factors that go into determining what materials should be mixed with the liquid metals. Read more on that through here.Below are the questions asked during the event, along with their respective answers.

Speaking in the same interview, Otori also confirmed that Sony will continue to improve and optimize the PS5’s fan after the console’s launch with firmware updates. We took more than two years to prepare well to solve these problems.” In order to handle such materials, it is necessary to take measures for manufacturing equipment as well. Above all, it is highly corrosive to aluminum used for parts such as heat sinks. “ However, since liquid metal is conductive, if it leaks to the substrate side, it will be short-circuited. “I’ve always wanted to use liquid metal,” he said. Liquid metal TIMs usually go hand-in-hand with certain issues, and according to Otori, Sony spent two years coming up with solutions to these problems. Otori spoke more about the aforementioned difficulties in the manufacturing process as well. “Even after overcoming the difficulty of handling and adopting it in the manufacturing process, PS5 was finally able to adopt liquid metal, which is expected to have a great effect.” If you change to a TIM of 100 yen here, you can get the same cooling effect even if you use a heat sink of 500 yen. In other words, the total cost can be reduced. “ The standard for thermal design is to spend money near the heat source. As an analogy to general thermal design, let’s say you have a system cooling structure that costs 10 yen for a TIM and 1000 yen for a heat sink. “The main reason is cost,” Otori said when asked about why Sony decided to use a liquid metal TIM in the PS5. Even though a liquid metal thermal interface material (TIM) in isolation is costlier, it is effective enough that it allows Sony to go with cheaper components elsewhere. The PS5’s liquid metal cooling, for instance, was chosen for the console to reduce the overall cost of the cooling system. Similarly, they made cost-based decisions in other areas of the cooling system as well, as Yasuhiro Otori, the head of PS5’s mechanical and thermal design team, explained in a recent interview with 4Gamer. Sony have recently talked about how wanting to cut down the costs was one of the reasons for using a single large fan in the PS5 instead of two ( which is what resulted in the console’s large size). Earlier this year, reports began circulating that the PS5 would have an “unusually expensive” cooling system, and recent details that Sony have revealed about the console’s hardware have certainly fallen in line with that (and early impressions have suggested that the investment will pay off).

0 kommentar(er)

0 kommentar(er)